BMS and CTM explained

What is a BMS?

A Building Management System (BMS) is a computerized system that connects virtual or physical sensors and controllers. Its purpose is to monitor, optimize, and remotely operate all technical equipment within a building. These devices are grouped into several systems, which allows efficient and centralized management.

Typical systems controlled by a BMS include:

- HVAC (Heating, Ventilation, Air Conditioning)

- Lighting

- Electricity

- Security Systems

- Blinds and Shutters

- And more

By supervising all these systems together, a BMS provides a complete overview of the building’s technical performance.

What Is a CTM?

A Centralized Technical Management system (CTM) is a computerized system that centralizes and coordinates of one specific technical system only (in a building). Unlike a BMS, which manages all systems simultaneously, a CTM focuses on a single category, for example, security, lighting, or HVAC only.

This makes CTM a more targeted solution. It is often used as a component within a broader BMS architecture. In the case of a large buildings, multiple CTMs can operate at the same time, each managing its own system, while the BMS oversees the overall coordination.

What are the benefits of BMS and CTM?

Both BMS and CTM play a major role in improving building operations. They offer several key advantages:

- Energy efficiency: Promotes eco-friendly practices, contributing to reduced consumption and cost savings.

- Sustainable performance: Together, BMS and CTM contribute to a more efficient and sustainable operation of building installations.

- Improved safety: Continuous monitoring of security systems by BMS and CTM enhances building protection.

- Occupant comfort: Enhances comfort by allowing more precise control of environmental conditions, such as temperature and lighting.

- Reduced operating costs: Contributes to operational savings by optimizing the use of energy resources and minimizing waste.

- Reduced maintenance costs: Facilitates preventive maintenance, therefore reducing costs associated with unforeseen repairs and unplanned downtime.

The BACS Decree

This regulation applies only to France, but at the European level, a similar framework exists called EPBD. To learn more about this European directive, please refer to this link on EPBD compliance.

Definition

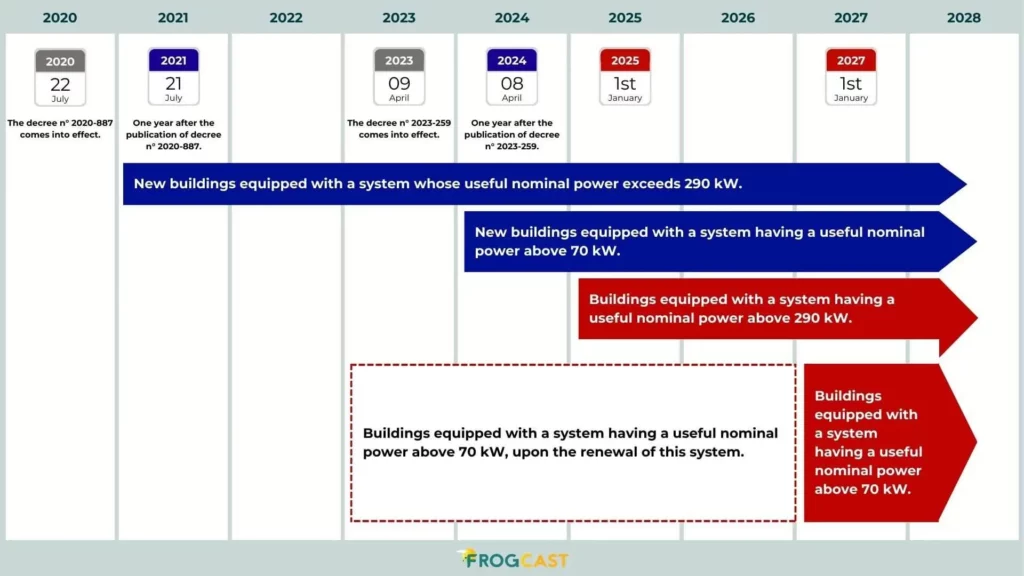

The BACS Decree (Building Automation & Control Systems), issued on July 20, 2020, defines how to meet the energy-reduction objectives outlined in the tertiary decree. This regulation requires the implementation of a building automation and control system in certain buildings, no later than January 1, 2025.

This decree represents the French implementation of the European Directive on the Energy Performance of Buildings (EPBD). As a result, all European Union countries have similar obligations to install Building Management Systems (BMS) or Building Automation Systems, though each country enforces these requirements through its own national laws under different names.

Objectives of the BACS Decree

- Monitor, record, and analyze energy consumption

- Adjust the operation of technical systems in real time based on actual needs

- Detect and alert operation managers of potential consumption drifts, upstream of malfunctions, to avoid overconsumption and additional maintenance costs.

Deadlines

The implementation deadlines depend on the building category and the nominal power of heating or cooling equipment:

- Existing tertiary buildings (≥ 290 kW): BMS mandatory by January 1, 2025

- Existing tertiary buildings (≥ 70 kW): BMS mandatory by January 1, 2027

- New buildings (permit after July 21, 2021, > 290 kW): immediate requirement

- New buildings (permit filed in 2024, > 70 kW): mandatory starting 2024

BMS performance classes

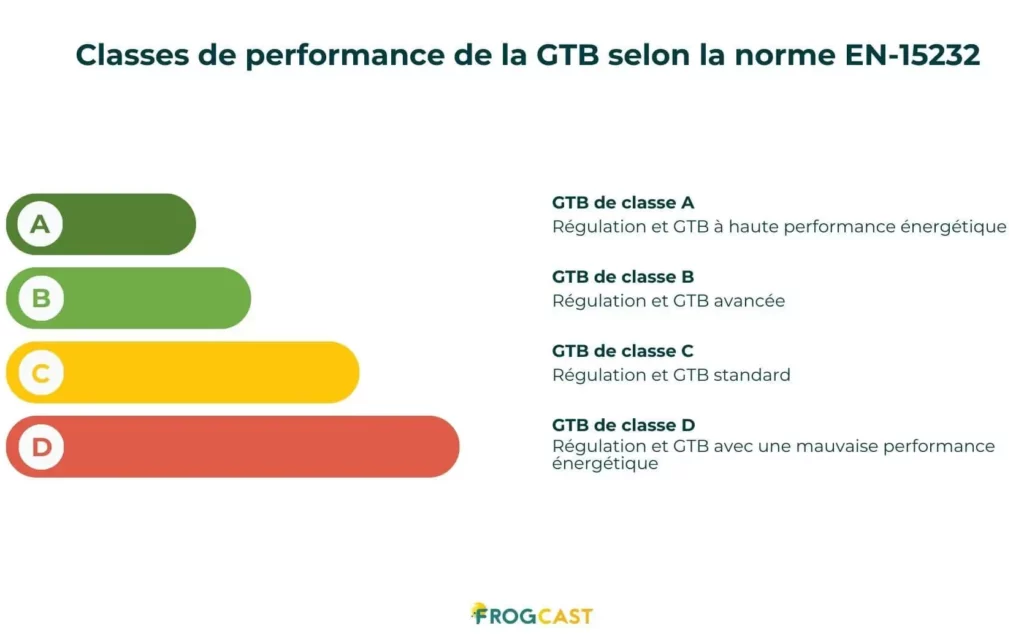

The standard NF EN ISO 52120-1:2022 describes the functions related to automation, regulation, and technical management impacting the energy efficiency of buildings. It defines four performance classes for BMS A, B, C, and D.

- Classes A, B, and C are aligned with the energy-efficiency targets of the BACS decree.

- Class D does not meet these requirements and is therefore not considered here.

All classes A to C aim to reduce the energy consumption and CO₂ emissions of major equipment such as heating, air conditioning, lighting, and hot water production. Depending on the class and level of control, a BMS can decrease energy bills by 5% to 40%.

Installing a BMS also gives access to an EEC financial bonus, which increases with the performance class; the higher the energy efficiency of your BMS, the higher the bonus.

Focus on class A BMS

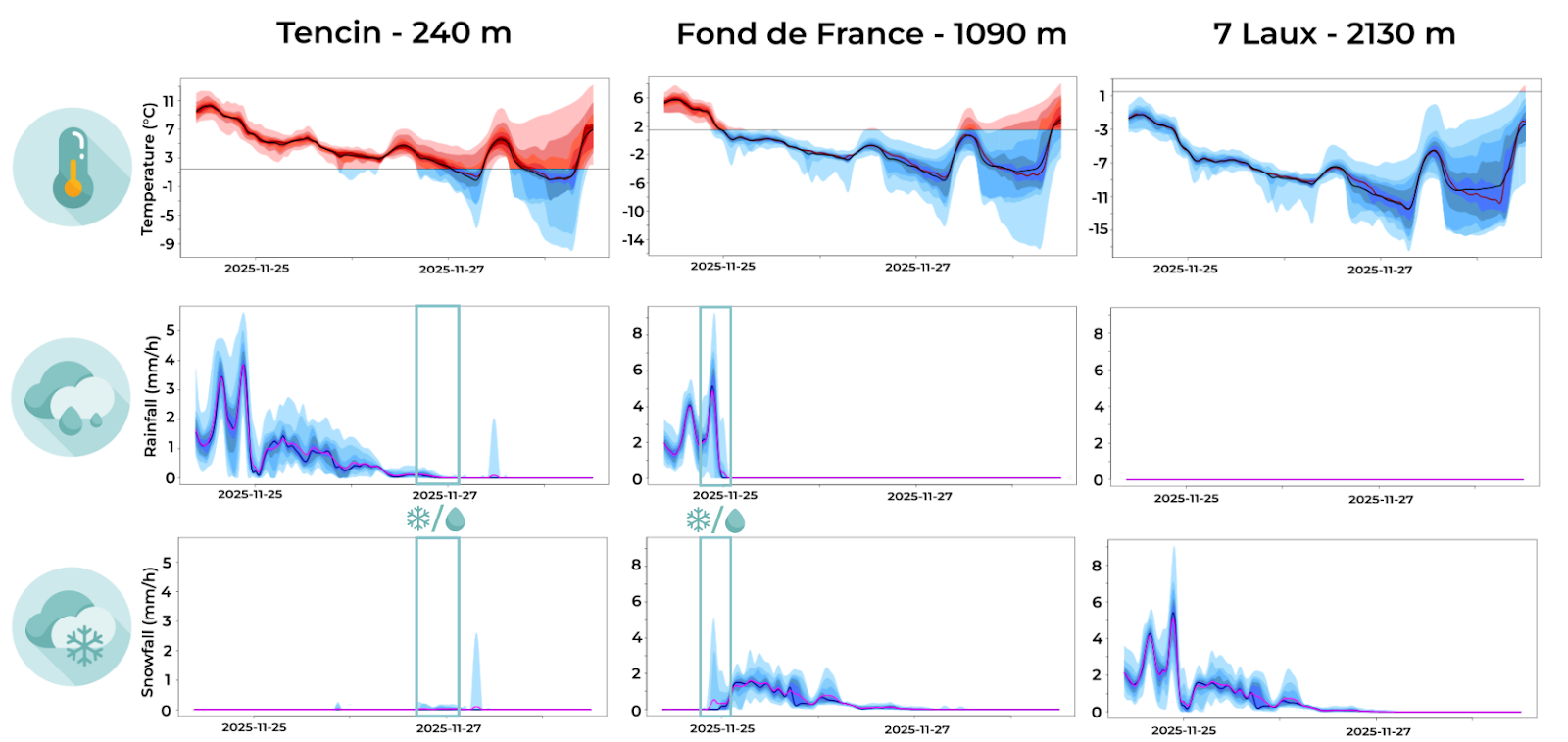

Types A and B require sensors to operate, and these sensors can be either physical or virtual.

For a BMS to be considered Type A, it must integrate predictive capabilities. It uses algorithms and data, including weather forecasts, to anticipate future needs and building conditions. This can include, for example, forecasts of energy consumption, potential breakdowns, maintenance requirements, and other relevant parameters.

A Type A BMS therefore ensures better energy efficiency, reduced operating costs, proactive breakdown management, and optimized building performance. It also helps improve decision-making by anticipating future needs and automatically adjusting various equipment accordingly.

Practical example: Heating and temperature control

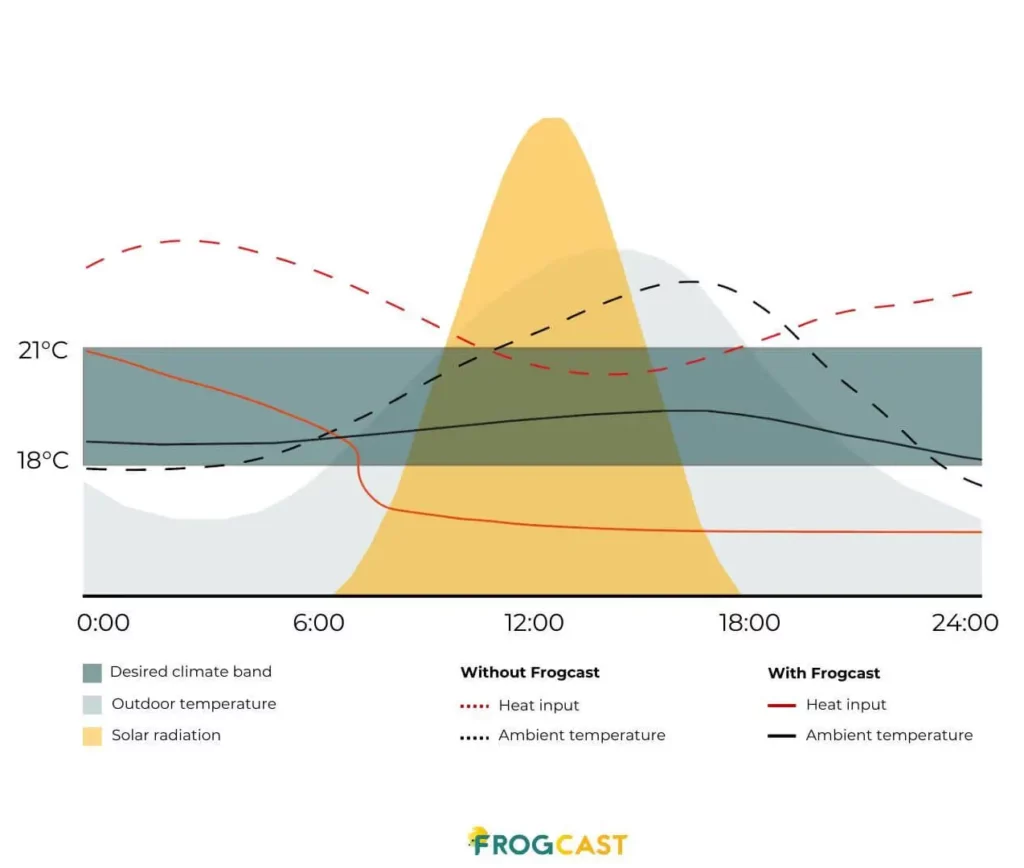

Let’s consider a heating system aiming to maintain indoor temperatures between 18°C and 21°C (shaded zone on the graph).

Without anticipation

First scenario, if the system does not account the upcoming weather conditions throughout the day, it reacts only to the current indoor temperature. The ambient temperature (black dashed line) being below the desired temperature, the heating system will start with a significant heat input (red dashed line) to allow the ambient temperature to reach the desired values. Once the temperature threshold is reached, the heat input is reduced.

The problem appears later in the day:

- The outdoor temperature (light green) rises quickly.

- Solar radiation (yellow) also increases significantly.

- Because these changes were not anticipated, the indoor temperature exceeds the 21°C limit, even though the heating input is already lowered.

Later, when the outdoor temperature drops again at night:

- The system has not anticipated the cooling phase.

- The indoor temperature falls below 18°C.

- A new, strong heating input is required to compensate.

This creates unnecessary energy consumption and fluctuating comfort for occupants.

With weather-based anticipation

When the system anticipates temperature changes and solar radiation:

- The heating input is gradually adjusted throughout the day.

- Temperature remains within the desired comfort range.

- Energy consumption decreases, and the heating system works more smoothly.

This predictive approach ensures energy and cost savings, but more importantly, it improves the inhabitant’s comfort by maintaining the ambient temperature within the desired climatic range.